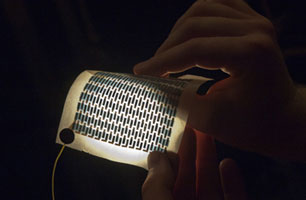

MIT graduate student Miles Barr hold a flexible and foldable array of solar cells that have been printed on a sheet of paper. Patrick Gillooly | MIT

Ah, solar panels: so clean, so elegant—and so bloody expensive. Covering your roof with photovoltaics may save you money in the long run, but it requires the installation of a lot of heavy and expensive equipment up front. Thin-film solar panels, printed on sheets at industrial scales, are slowly making inroads, but suppose you wanted to power something much smaller than a house — an appliance or an alarm clock, say. Never mind waiting for industry to invent the product you’re waiting for. According to a paper published in the journal Advanced Materials, it’s now possible to print photovoltaic cells on paper almost as you would a document — and almost as cheaply too.

The improbable new “solar papers,” developed by a team of MIT researchers, start out looking like an ordinary sheet of paper — and that’s because they are. Anything from printing paper to tissue, tracing paper, or newspaper can be used. It’s what happens next that’s special. As the paper is run through the solar printer, it enters a vacuum chamber, where a spray of photovoltaic material passes through a mask in the shape of solar cells and is deposited onto the surface of the sheets. After five such layers are applied, a functioning photovoltaic device emerges from the other end. The work any one sheet can do is modest, but it’s real all the same. In an MIT video, a researcher clips some wires to one end of a paper and shines a light onto it. An LCD clock at the other end of the wires starts to display the time.

There are a lot of things that make solar paper preferable to traditional panels — particularly the radical difference in cost. Conventional solar cells waste a lot of money on inactive components – especially the substrate, typically glass, used to support the active photovoltaic stuff. Researchers note that paper costs one-thousandth as much as glass for a given area. Then there’s the printing process itself. Conventional panels rely on expensive chemicals deposited at very high temperatures. The MIT printer uses cheaper vapor deposition and can operate at temperatures below 120C (248 F). That’s hot, but nothing compared to the 800C (1,470) needed for today’s panels.

More from TIME: Betting on Big Solar

Solar paper is also rugged. Print it out and you can fold it up and tuck it in your pocket without damaging its light-reactive surface. The MIT scientists demonstrated this quality by printing one of the cells onto a sheet of PET plastic, which is thinner than the stuff used for soda bottles, and folding and unfolding the plastic 1,000 times. The cells performed at the same level even after all that abuse, whereas commercially produced solar cells printed on the same material usually crash after just a single folding.

“Often people talk about deposition on a flexible device — but then they don’t flex it, to actually demonstrate [that it can survive the stress],” study author Karen Gleason said in a press release. She and her team also ran a sheet through the high temperatures of a laser printer to demonstrate that it would still function — and it did. And solar cells produced a year ago are still working, which shows that they last for quite a while.

More from TIME: See the top 20 green tech ideas.

Nobody pretends that solar paper is ready to make a big dent in the world’s energy problem just yet. Odds are you don’t need to operate your alarm clock outside and there are already plenty of small electronic items manufactured with small, old-fashioned solar panels built in just in case you do. But as a proof of principle — that principle being that you don’t have to go broke to go green — the MIT announcement is a very important one. Put together enough of those small steps and, over time, you can get where you’re going.

Tara Thean is a TIME contributor. Find her on Twitter at @TaraThean. You can also continue the discussion on TIME‘s Facebook page and on Twitter at @TIME.

Photos from TIME: Solar-Powered Airplane Takes Flight

More from TIME: See the surprisingly long history of green energy.